Porcelain tile adhesive

Porcelain tile is a popular type of tile made from high-quality ceramic powders. After firing at high temperatures, it takes on a smooth and shiny surface. Porcelain tile adhesive

Where is it used?

Due to its beauty and durability, porcelain tile is widely used on walls and floors, both indoors and outdoors. This stylish tile not only has practical applications, but also adds a unique look to the design of various spaces. As a high-quality product, this adhesive has a wide range of applications in the installation of tiles, ceramics, and natural and artificial stones.

Interior wall floors

Choosing the right adhesive is important for installing ceramic tiles on the floors and walls of interior buildings, including bathrooms, kitchens, and living rooms. This adhesive, with its high adhesion and moisture resistance, is a suitable option for these spaces.

External surfaces

It is a suitable choice for installing tiles in outdoor spaces such as terraces, balconies and building facades.

Inappropriate levels

Due to its special composition, this adhesive allows tiles to be installed on unsuitable surfaces such as concrete, plaster, and even old tiles.

Pools and wet environments

Due to its high water resistance, it is very suitable for installing tiles in swimming pools and humid environments.

Types of porcelain tile adhesives

- White porcelain powder adhesive: The best option for installing light and white tiles, which creates beautiful and uniform surfaces.

- Gray porcelain powder adhesive: Suitable for darker and colored tiles, this adhesive provides a uniform and harmonious background.

- Quick-drying porcelain powder adhesive: Allows for faster installation of tiles and helps in construction projects.

Porcelain powder tile adhesive production process

- Selection of raw materials: Including Portland cement, silica sand, polymers, resins, and chemical additives that are carefully selected and combined to achieve the desired properties.

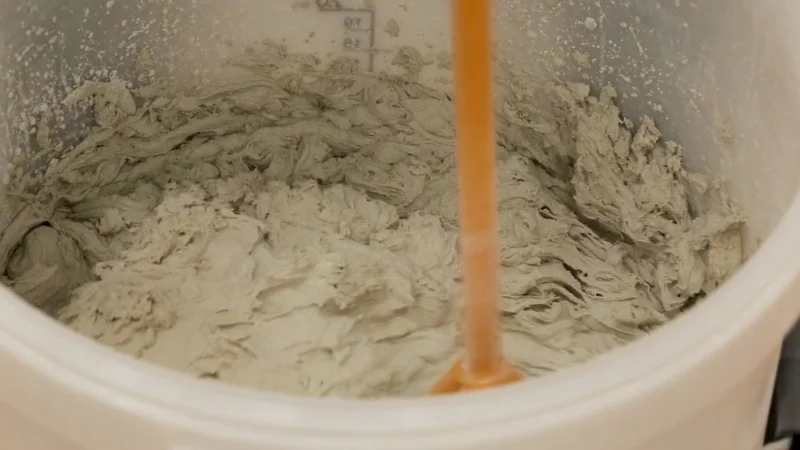

- Mixing materials: The raw materials are mixed together in specific proportions. This mixture must be uniform and lump-free, and industrial mixing machines are used for this purpose.

- Drying: The resulting mixture is converted into a dry powder. This step may involve drying at a controlled temperature to remove excess moisture.

- Packaging: The dried powder is placed in appropriate packaging and prepared for use.

By adding water in the right proportion, this adhesive turns into a sticky paste that is suitable for installing porcelain tiles. This production process guarantees the quality and high performance of the adhesive.

Tiles suitable for porcelain powder tile adhesive

- Porcelain tiles: Porcelain powder tile adhesive is specifically designed for this type of tile. With high density and low water absorption, these tiles require strong adhesion, which this adhesive provides well.

- Ceramic tiles: This adhesive is also very suitable for installing ceramic tiles, especially in humid environments such as bathrooms and kitchens that require greater adhesion and resistance.

- Artificial and natural stones: Porcelain powder tile adhesive can also be used to install artificial and natural stones such as granite and marble and adheres well to these surfaces.

- Large tiles: Due to its high adhesion and resistance to moisture and temperature, this adhesive is very suitable for installing large and heavy tiles and ensures their high durability.

Features of porcelain powder tile adhesive

- High adhesion: Due to its special ingredients, this adhesive has very high adhesion and prevents tiles from sagging.

- Resistance to water and moisture: With polymers and chemical additives, this adhesive is resistant to water and moisture and is suitable for bathrooms and kitchens.

- Flexibility: Porcelain tile adhesive has good flexibility and can withstand temperature changes and surface expansion.

- Durability against temperature changes: Due to its special compounds, this adhesive performs well in different temperature conditions.

- Resistance to chemicals: This adhesive is resistant to chemicals and can be used in environments containing these substances.

- Appropriate open time: The open time of this adhesive, meaning the usable time after application, is usually between 20 and 30 minutes.

- Compatibility with underfloor heating systems: Due to its flexibility and heat resistance, it is very suitable for underfloor heating systems. These features contribute to the durability and longevity of the tiles.

Steps to use porcelain tile adhesive

- Surface preparation: The surface to be painted must be clean, dry and dust–free. If the surface is uneven, smooth it.

- Mixing the glue: Pour a sufficient amount of powdered glue into a bucket and gradually add water. Stir the mixture until it reaches a smooth, lump-free consistency.

- Apply the adhesive: Using a notched trowel, spread the adhesive evenly over the surface. Hold the trowel at a 45-degree angle to create channels in the adhesive.

- Tile installation: Carefully place the tiles on the adhesive and rotate them with gentle pressure to remove air between the tiles and the adhesive. Use spacers to adjust the gaps.

- Drying: Allow the adhesive to dry completely. This usually takes between 24 and 48 hours, depending on environmental conditions.

- Grouting: After the adhesive dries, fill the gaps between the tiles with grout and clean the surface.

How to maintain porcelain tile adhesive

- Storage location: Store the glue in a cool, dry place. Moisture can reduce the quality of the glue.

- Packaging: Seal the adhesive packaging well to prevent air and moisture from entering. If the packaging has been opened, use strong plastic bags to repack.

- Ambient temperature: Store the adhesive at a temperature between 5 and 30 degrees Celsius. Extremely high or low temperatures can damage the chemical composition of the adhesive.

- Expiration date: Pay attention to the expiration date of the adhesive and do not use expired adhesives. Expired adhesives may not be as effective.

- Away from chemicals: Keep the adhesive away from strong and corrosive chemicals to prevent unwanted reactions.

The difference between porcelain powder tile adhesive and porcelain paste tile adhesive

1- Ingredients:

- Powder: This adhesive is made based on cement and includes polymers, mineral fillers, and adhesive additives that increase strength and high resistance.

- Paste: This adhesive is based on acrylic resin and contains synthetic polymers, micronized mineral fillers, and chemical sealants.

2- Preparation:

- Powder: It is in powder form and must be mixed with water to form a paste and be usable.

- Paste: It is ready to use and does not need to be mixed with water or other ingredients.

3- Places of use:

- Powder: More suitable for places exposed to moisture and has high resistance to water.

- Paste: More suitable for dry places and interior walls and has less sealing properties.

4- Drying time:

- Powder: Usually dries in about 24 hours.

- Paste: has a longer drying time and may take up to 72 hours.

Conclusion

Applied adhesive

Porcelain powder tile adhesive is a good option for a variety of construction projects.

High quality

The unique properties of this adhesive ensure a strong and stable installation of tiles.

Observing the tips

Attention to instructions and storage conditions is essential for optimal adhesive performance.